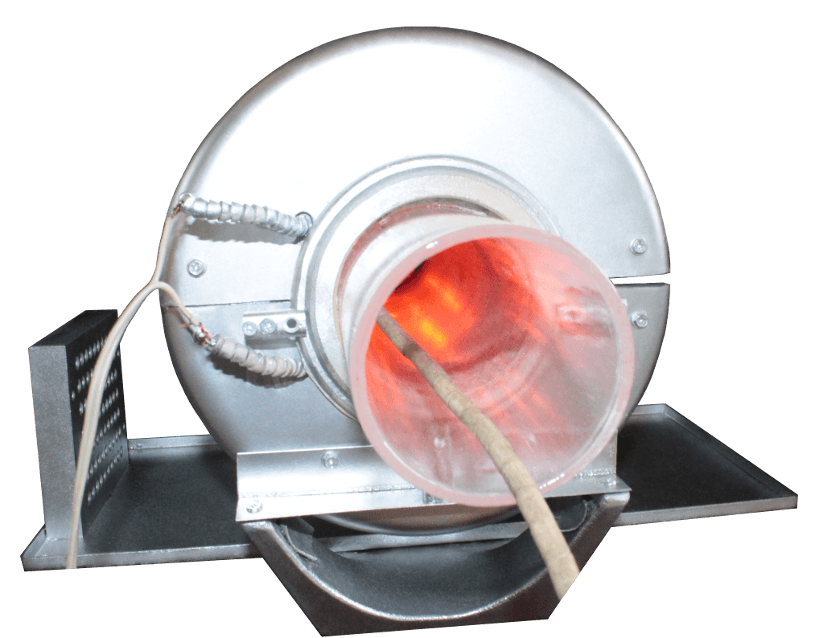

Quartz furnace

Quartz furnace is a device consisting of a quartz tube, the ends of which have flanges for evacuating the reactor to create a special or gaseous medium. The required temperature is maintained in the electric furnace reactor, which can be located outside the reactor, and inside. Quartz glass - is a one silicate glass, consisting of almost pure silica.

Quartz furnace is a device consisting of a quartz tube, the ends of which have flanges for evacuating the reactor to create a special or gaseous medium. The required temperature is maintained in the electric furnace reactor, which can be located outside the reactor, and inside. Quartz glass - is a one silicate glass, consisting of almost pure silica.

Silica in the silica glass is in an amorphous state, so has a very low coefficient of thermal expansion and thermal conductivity and a sharp temperature drop does not crack. The almost complete absence of impurities in the quartz glass causes the following characteristic properties: a small light absorption, a wide range of transmission, resistance to laser and ionizing radiation, low coefficient of thermal expansion. All these qualities are determined by applying the material in reactors.

Using a quartz reactor in different areas of production, physical and chemical laboratories, laboratories of innovative enterprises will make possible the implementation of numerous, costly, complex and difficult to control operations. The advantages of the quartz reactor - a relatively low cost, compactness, portability, versatility, uniqueness. Quartz reactor can work independently and as part of processing modules with remote control.

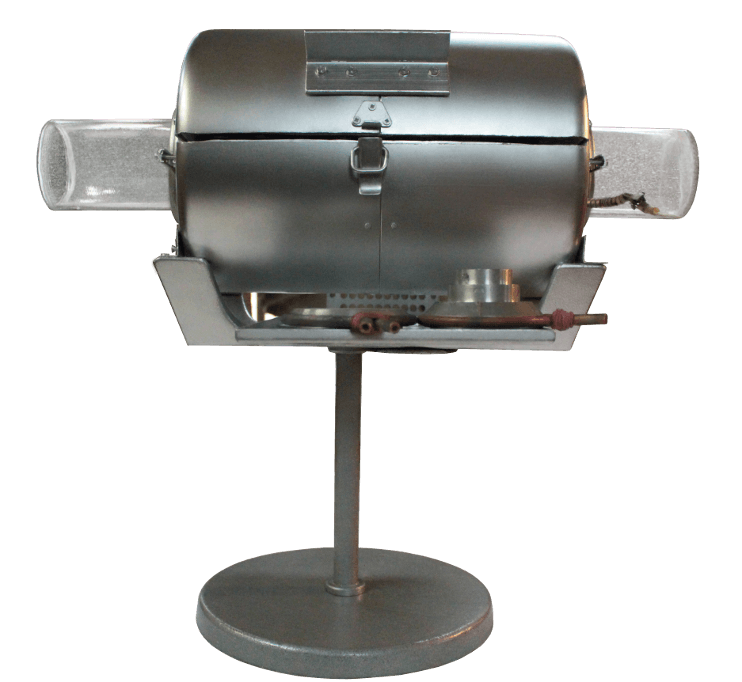

A quartz reactor with an electronic control unit

Reactor accompanied microprocessor control system, which provides:

• reactor operation in the automatic mode;

• stabilization and control of technological parameters;

• diagnostics system components;

• archiving the data and create a library of recipes process.

Characteristics of the reactor

|

Dimensions of the working area of the reactor

|

Length - 10-100 cm - diameter 10-120 mm

|

|

Pressure (vacuum or controlled atmosphere)

|

from 0.1 Pa to 3 MPa

|

|

Operating temperature range

|

From room temperature to 1200 оС

|

|

Reactor control

|

Computer temperature control using the electronic control unit with microcontrollers

|

|

Accuracy of temperature regimes

|

The control unit allows to the degree to define complex temperature regimes

|

|

Methods of the reactor

|

Possible to produce the heating furnace, both outside and inside the cylindrical reactor

|

|

Basic equipment

|

Quartz reactor with oven, end flanges, control, pressure control, pumping system and vent the atmosphere, cooling system flange

|

|

Additional equipment (on request)

|

Upon request, can be supplied laptop, vacuum pump, buffer chamber for mixing gases, etc.

|

|

Power / Power Consumption

|

220 V (50 Hz) / 2 kW max

|

|

Cooling system

|

Water cooling system flanges closed system without external water liner

|